Snow Storages for Nordic Skiing

Guaranteed season start of specific ski track or ski jump

Make snow in optimum conditions

- Can be made during the cold periods in the winter to minimise energy consumption.

Image by Jerzy Górecki from Pixabay

Shape of snow storage is adapted to location.

Ruka Nordic Ski Stadium

Snow melting less than 10% from April to September

Example of shape for Nordic Skiing

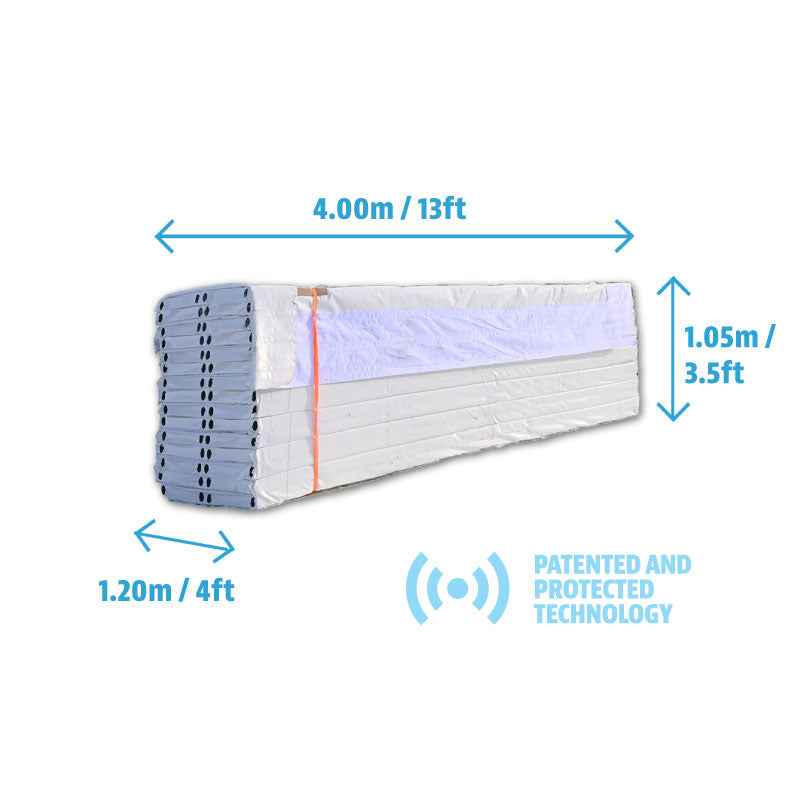

Patented snow storage system

- Scalable solution

- Suitable to store even long and small or high and large snow storages

- Patented integrated rain and wind cover system

Extremely fast installation

Snow storage can be covered within few hours, same with dismounting

Hybrid solution with saw dust

Snow Secure solution can be also combined with saw dust where applicable.

Reference Kauppi, Tampere, Finland

Works also in low altitudes!

- Daily 24 hour average temperatures can be even above 70°F

- Works even at the sea level!

TEMPERATURE MEASUREMENT IN TROMSØ: JUL 6 - AUG 26, 2024

-

BELOW THE INSULATION MAT

-

ABOVE THE INSULATION MAT

7h Installation in Oittaa

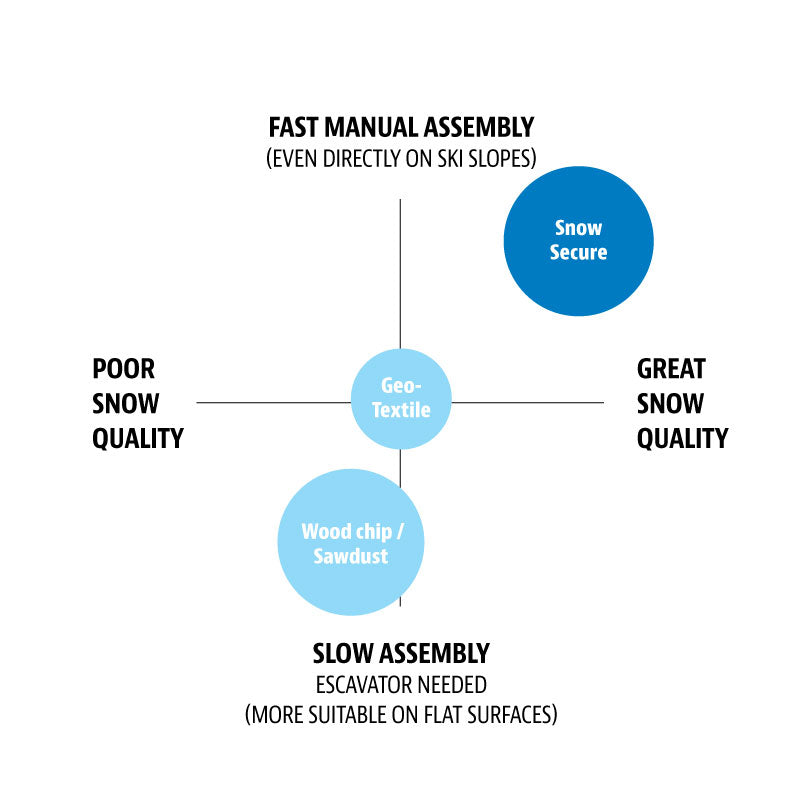

Snow Secure provides best overall performace

Assembly Speed vs Snow Quality

Size of circle = Relative amount of snow in the autumn